Drum wood chipper machine used for wood chipper

Drum chipper is a special equipment for the production of wood chips. It is widely used in particle board factory, medium, high, density fiberboard factory, Straw crops, bio-power plant, wood chip factory, etc. and the preferred equipment before the preparation section in the production of the manufacturer. The product has advanced structure, good quality of cutting flakes, wide adaptability of raw materials and convenient operation and maintenance. The main raw materials for cutting are small-diameter wood, wood harvesting and processing residues, etc., and can also be used to cut non-wood raw materials (such as: sugar cane, bamboo, reed, etc.)

Category:

Pulverizer

Drum wood chipper machine used for wood chipper

1. Product introduction

Drum chipper is a special equipment for the production of wood chips. It is widely used in particle board factory, medium, high, density fiberboard factory, Straw crops, bio-power plant, wood chip factory, etc. and the preferred equipment before the preparation section in the production of the manufacturer. The product has advanced structure, good quality of cutting flakes, wide adaptability of raw materials and convenient operation and maintenance. The main raw materials for cutting are small-diameter wood, wood harvesting and processing residues, etc., and can also be used to cut non-wood raw materials (such as: sugar cane, bamboo, reed, etc.)

2.Product Advantage:

Advanced product structure, good cutting stump quality, adaptable raw material, conveninet operatin and maintenance.

3.Product Component

The machine is composed of body, knife roll, feeding roller, conveyor belt and hydraulic system.

The body is welded with high strength steel plate, which is the support base of he whole machine.

Hydraulic system:from oil pump to oil cylinder,could be started the lid, replace the blade, it can lift on the feeding roller assembly when maintenance, easy to adjust the fly knife, bottom knife gap and comb plate dismantling.

4. Product specification

|

Type |

HL216 |

HL217 |

HL218 |

|

Diameter of knife roll(mm) |

650 |

650 |

800 |

|

Blade(sheet) |

2-3 |

2-3 |

3-5 |

|

Inlet size(mm) |

240×540 |

240×700 |

350×700 |

|

Knife roll speed(r/min) |

590 |

590 |

560 |

|

Feed speed(m/min) |

38 |

38 |

38 |

|

Max diameter (mm) |

200 |

200 |

300 |

|

Length of wood(mm) |

20-35 |

20-35 |

20-35 |

|

Production capacity(t/h) |

6-8 |

8-12 |

10-15 |

|

Main motor power(kw) |

55 |

75 |

110 |

|

Weight(t) |

4.07 |

5.2 |

7 |

|

Dimension(mm) |

1980×1950×1250 |

2300×2150×1500 |

2300×2150×1500 |

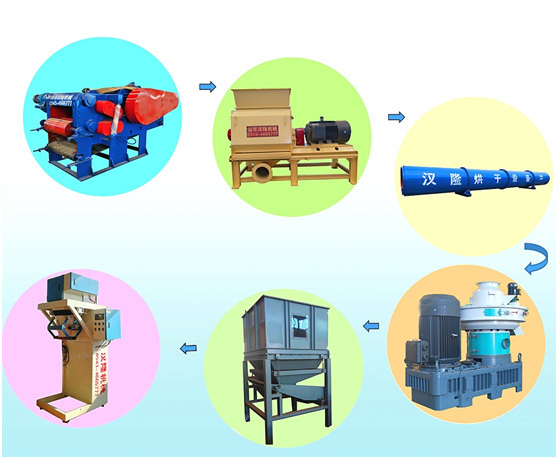

5. Processing

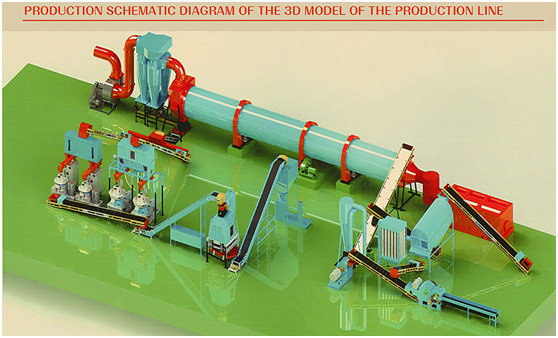

6.3D Vertical Total Processing Picture

7. Certification

8. FAQ

Q: Are you trading company or manufacturer?

A: We are manufacturer.

Q:How long is your products' lifetime?

A:Products' life time is based on the working condition,pls tell us your working condition, let us give you more technical suggestion.

Q:Could you do OEM and ODM.

A:Certainly, welcome ODM and OEM.

Q:What is the delivery time?

A:In general, usually our delivery time is 30 days, while we could arrange the producing scheduling as customer requirements.

Leave A Message

CONTACT US

Contact:Mr. Lin

Phone: 0086 18265706999

Email: zoupinghanlong@163.com

Add: Daqi economic development zone, Zouping city , shandong province ,China

MESSAGES

©2023 Hanlong machinery (Shandong) Co., Ltd