HL560 Vertical Ring Die Pellet Machine

The vertical ring die machine produced by our company absorbs the essence of foreign pellet machine. The “pressure wheel” is made of high alloy wear-resistant material. It has the characteristics of unique design, reasonable structure, high efficiency, long life and so on. The unit carefully developed the domestically established stereotyped products, which filled the blank of the national circular mold granulation vertical feeding and reached the international advanced level. This product is suitable for pressing materials that are difficult to bond and difficult to form. Such as: rice husk, sunflower seed shell, peanut shell and other melon and fruit shells, branches, tree stems, bark and other wood scraps, a variety of crop straw and other raw materials. It is applied to feed mills, wood processing plants, fuel plants, fertilizer plants, etc. It is the ideal compact compression molding equipment with small investment, quick effect and no risk.

Category:

Biomass Pellet Machine

Key words:

HL560 Vertical Ring Die Pellet Machine

1. Product introduction:

The vertical ring die machine produced by our company absorbs the essence of foreign pellet machine. The “pressure wheel” is made of high alloy wear-resistant material. It has the characteristics of unique design, reasonable structure, high efficiency, long life and so on. The unit carefully developed the domestically established stereotyped products, which filled the blank of the national circular mold granulation vertical feeding and reached the international advanced level. This product is suitable for pressing materials that are difficult to bond and difficult to form. Such as: rice husk, sunflower seed shell, peanut shell and other melon and fruit shells, branches, tree stems, bark and other wood scraps, a variety of crop straw and other raw materials. It is applied to feed mills, wood processing plants, fuel plants, fertilizer plants, etc. It is the ideal compact compression molding equipment with small investment, quick effect and no risk.

2.Application:

This is a high-density pellet equipment which is widely used for the waste recycling in biomass energy plant, power plant, wood processing plant, chemical plant, food products facotry ,winery plant etc.

3. Applicable raw materail

Raw materials which are hard to be bounded and shaped such as husk(rice husk, sunflower seed husk, peanut shell etc) Wood scraps(branches, trunks, barks, sawdust etc.)crop straw, eucalyptus, palm thread, coffee husks, cocoa husks, etc.

4. Working principle:

This machine adopts two-stage-drive system, The transmission shaft is connected to the principle axis via belt pulley, which enables the pinch roller to roll the internal surface to complete the presssing process.

During the process, raw material fell on the rotaing plank through the feeding hole, then equispaced on the surface of the die inner cavity via rotation of the plank, After rolling by pinch roller, the powdery material will go through the die hole under the effect of high pressure and high temperature.

During this process, the material will turn into cylingdrical solid form under physical change and some chemical change. This cylindrical solid form will grow longer and longer through the hole until it was cut by the blades equispaced aroungd the die.

Then the pellets take shape. The pellets will be collected to the dischage hole by the ejecting device, then fall down under gravity, until now, the whole process of the pelletizing finishes.

5. Advantage:

1. Feeding vertically

2. Ring Die

3.Independent ejection device

4.Enviromental and energy -saving

6. Specification

|

Type |

HLER560 |

HLER580 |

|

Output(t/h) |

1-1.5 |

2.5-3.5 |

|

Power(kw) |

90 |

220 |

|

Processing specification(mm) |

φ4-12 |

φ4-12 |

|

Weight(t) |

6.1 |

14.5 |

|

Size(mm) |

2600X1300X2300 |

3300X1400X3100 |

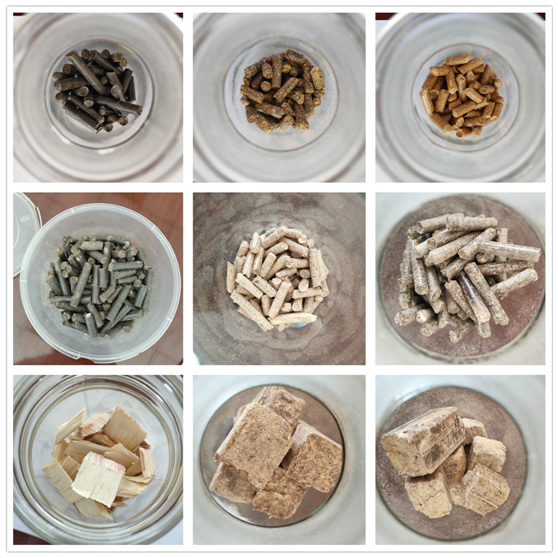

7. Particle Picture:

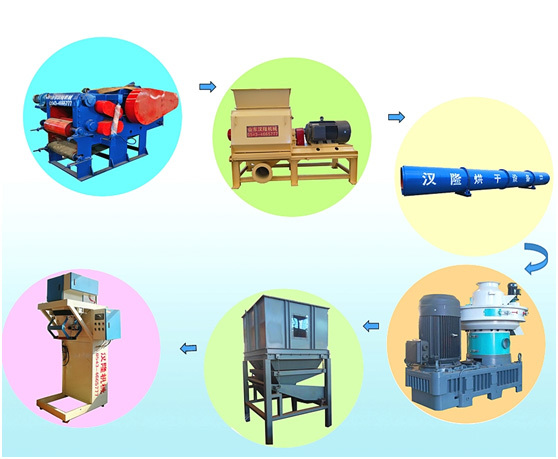

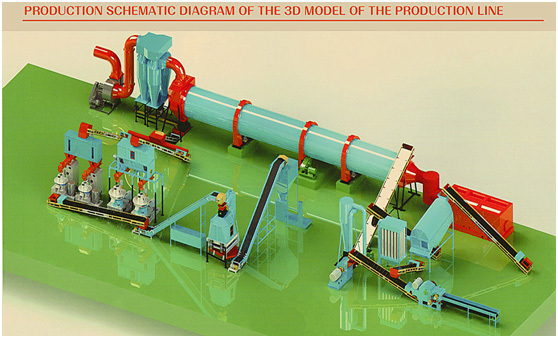

8. Process picture:

8. Company Information:

(a) Shandong Hanlong Machinery Manufacturing Co.,Ltd. in Zouping, Shandong Province,founded in 2009 with registed capital of 20 milliion Yuan. The company has more than150 employees, including more than 60 mechanical professionals and technicians.

(b) It has passed ISO9001, ISO14001, OHSA18001, SGS, EU CE certification, international quality management system certification.

(c) The company's products include:drum chipper, disk chipper, log pickpocket machine wood chipper, stump crusher, biomass energy equipment, sawdust granular,vertical ring die pellet mahcine, granular cooling mahcine, full-automatic packaging machine,airflow dryer, drum dryer etc.

(d) At present, the company has more than 30 equipments such as large numerical control machining center, large numerical control gantry milling machine, large numerical control boring machine, numerical control die processing center and large dynamic balance machine.

(e) The quality of life is provided by Hanlong! Good reputaiton and first-class after-sale service.

9. Transporation:

10 Certification:

11. FAQ:

Q: Are you trading company or manufacturer?

A: We are manufacturer.

Q:How long is your products' lifetime?

A:Products' life time is based on the working condition,pls tell us your working condition, let us give you more technical suggestion.

Q:Could you do OEM and ODM.

A:Certainly, welcome ODM and OEM.

Q:What is the delivery time?

A:In general, usually our delivery time is 30 days, while we could arrange the producing scheduling as customer requirements.

Q:What is the payment term accept?

A:30%T/T in advance, the balance pay off before delivery.

Prev

Next

Prev

Next

Leave A Message

CONTACT US

Contact:Mr. Lin

Phone: 0086 18265706999

Email: zoupinghanlong@163.com

Add: Daqi economic development zone, Zouping city , shandong province ,China

MESSAGES

©2023 Hanlong machinery (Shandong) Co., Ltd